True Colors

.jpg)

True Colors at Bright Moments gallery in Berlin

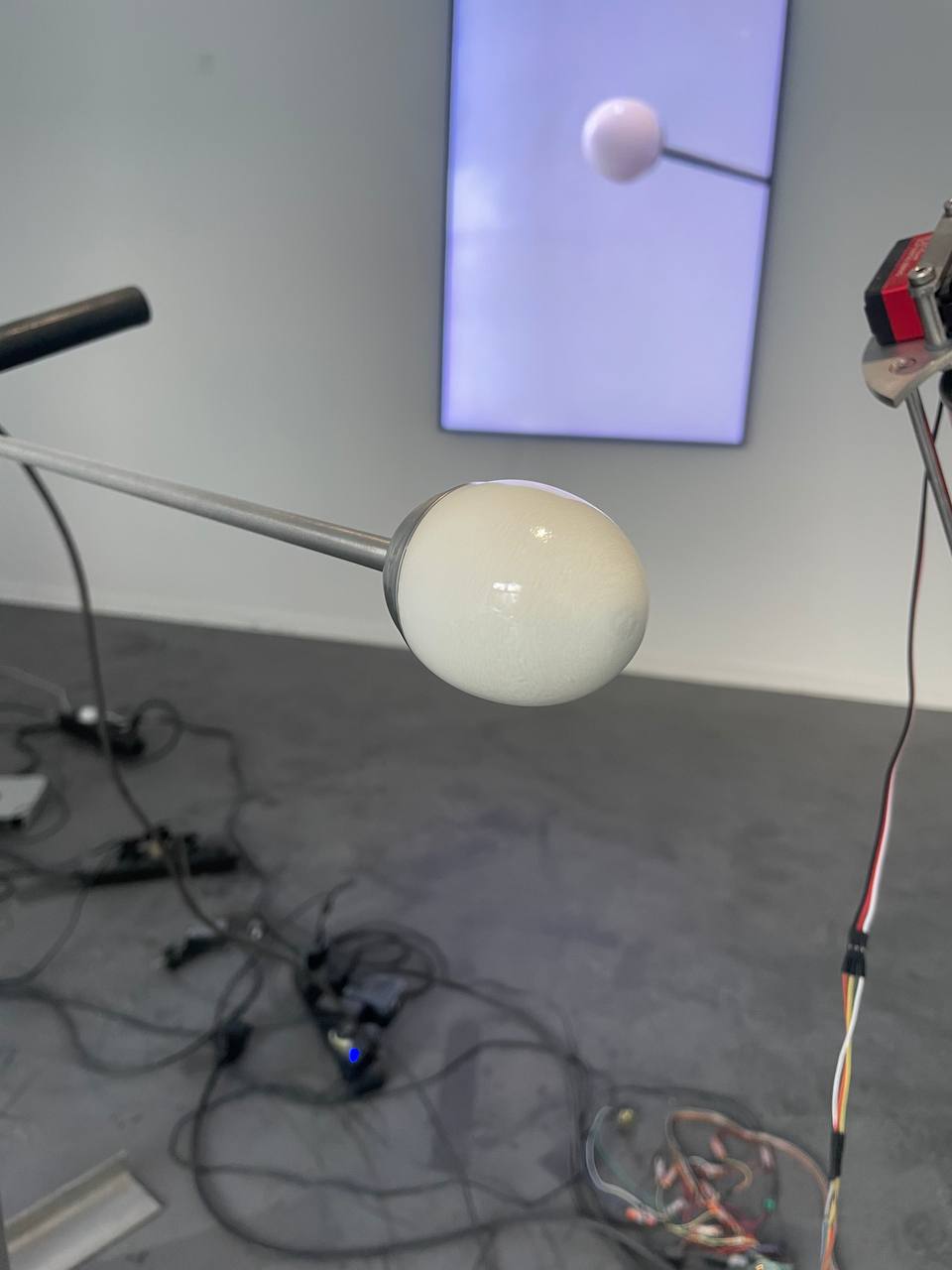

An egg is attached to a steel rod, which is slowly rotated by a vintage gdr drill machine.

Clear varnish is being sprayed periodically onto the rotating egg, resulting in cumulative layers of drying

varnish.

The solvent in each spray will loosen the existing varnish on the egg, resulting in an everlasting cycle of

softening and hardening of the varnish layers.

The installation was running 24/7 from the 25th of July until the 16th of August 2024, at Bright Moments

gallery in Berlin.

The spray can is manually replaced once per day.

This project was created in collaboration with Pedro Moraes.

Exhibition poster

.jpg)

Vernissage

The exhibition is running 24/7

Daily updates

.jpg)

.jpg)

After 2 days

.jpg)

.jpg)

.jpg)

After day 3 the egg adapter broke and the egg fell

.jpg)

.jpg)

.jpg)

A new egg adapter was installed. The egg was cooked in order to make it more stable.

Day 2 with new adapter

.jpg)

Day 4

.jpg)

Day 5

.jpg)

.jpg)

Day 6

.jpg)

Day 8

.jpg)

.jpg)

A big part dripped off.

.jpg)

.jpg)

Day 9

.jpg)

.jpg)

Day 11

.jpg)

Day 12

.jpg)

Day 16

References

Sui Jianguo, "Shape of Time (Day 1895)"

Henrik Menné

Eggs in art & design: https://www.are.na/laurel-schwulst/eggs-in-art-and-design

Process

.jpg)

.jpg)

.jpg)

Prototyping, 3d-modelling, 3d-printing: Ifigenia Dakouri

https://www.germanys-true-colors.de/Klarlack-fuer-Zweischichtlacke--400ml.html

Bohrmaschine DDR SBB 16i Hönnecke & Ditter Eibenstock https://www.ebay.de/itm/395061869483

.jpg)

.jpg)

Accumulating varnish residue

Every 5 minutes the spray can is auomatically spraying for 2 seconds. That's about 9:30min per 24h.

The spray nozzle is rated at ~17g per 10 seconds. One spray can has about 200-250g of actual varnish. (the

400ml on the label includes the solvent)

250/17*10=147s of continuous spraying per can.

Photo: Pedro Moraes

The first experiments of this have happened in 2020:

.jpg)

Two years of aging.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

First object (2020) was manually poured with varnish once per day.